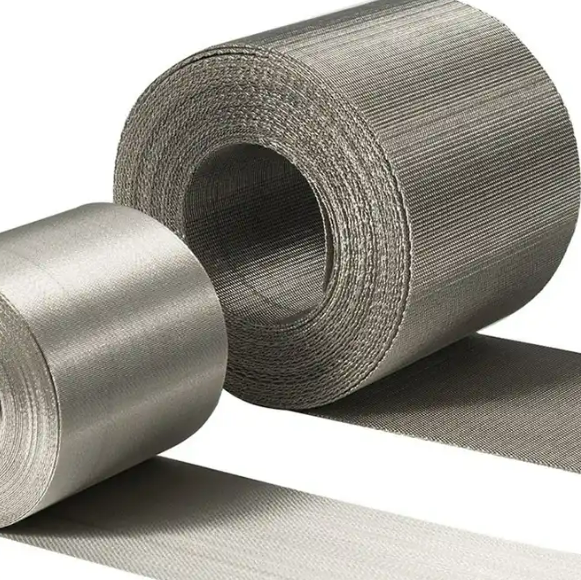

Product name: Stainless steel reverse dutch mesh belt

Item No.: TSMP- 47

Material: AISI 304 316

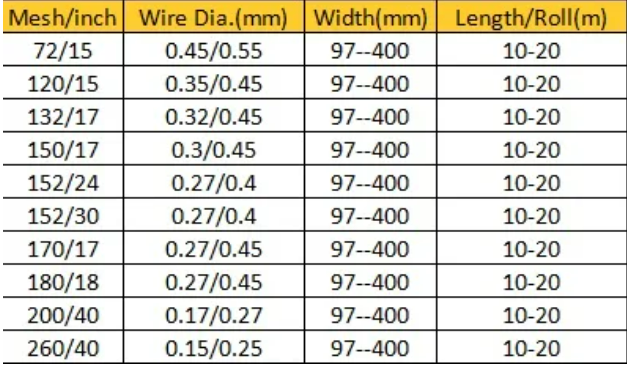

Hole size: 72x15 mesh, 150x17 mesh, 152x30 mesh, 260x40 mesh etc

Height: 0.3m-3m or as request

Length: 3-40m or as request

Package: plastic film inside, plywood case outside

OEM: acceptable

Color: silver color etc

Product introduction

Reverse dutch woven wire mesh is another product specially designed for filtering. It is mainly made of stainless steel wire,

which is chemical resistance, alkali and acid resistance, rust and corrosion resistance. It can ensure the durable filtering performance

during the usage. The reverse dutch weave can also be used in brass wire, which is also has chemical stability for filtering.

* Rubbed Edges after slitting to help with tracking for Auto-Screen changers.

* Plasma and laser cut parts to help prevent edges wire fraying.

* 100% Inspection of Wire Cloth for critical applications such as sand screens and aerospace applications

Reverse dutch woven wire mesh is widely used for filtering in various industries:

● Aerospace.

● Petroleum.

● Chemical industry.

● Machinery.

● Plastic products.

● Conveying.

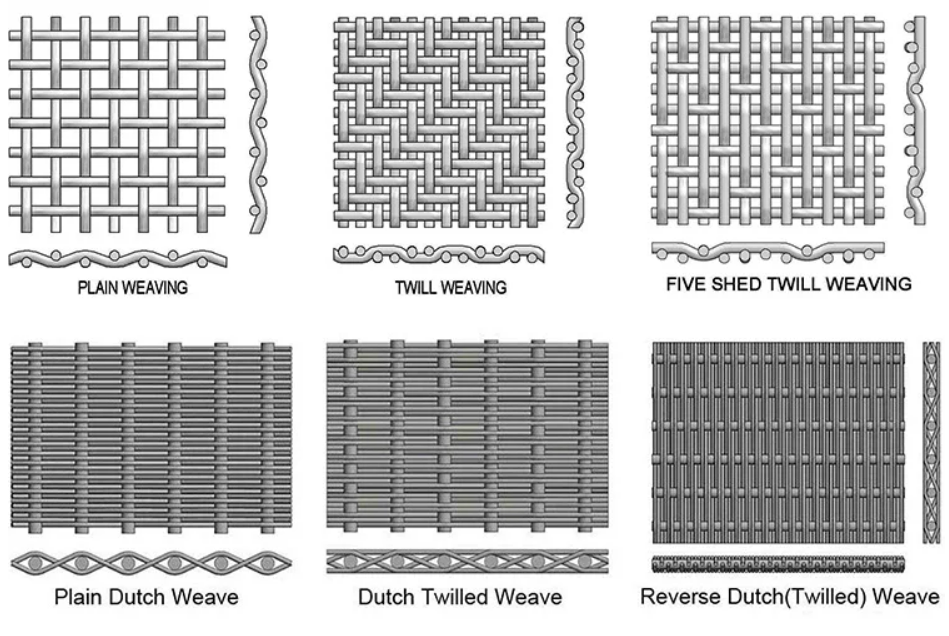

Weaving types and count

1. plain weave, also known as the tabby weave or linen weave, is the most basic and common weaving technique used to create fabric. It is characterized by a simple over-and-under pattern of interlacing warp and weft threads.

2. twill weave is a fundamental weaving technique used to create a specific pattern in fabric. It is characterized by diagonal lines or ribs that are formed by interlacing the warp and weft threads in a particular way.

3. Duch woven wire is a type of woven wire mesh with different diameters and mesh sizes of warp and weft threads. Reasonable combination of wire diameter and mesh size can achieve filtration accuracy that ordinary square mesh screens cannot achieve.

Knowledges of wire mesh

1. Mesh Count = 25.4mm/D+A

2. Aperture= 25.4mm/Mesh count - Diameter

3. % Open Area= A/(A+D)² X 100%

4. Micron= Aperture(mm) X 1000

5.Mesh – The number of openings per lineal inch.

6.Aperture- The distance between two adjacent wires

7.Diameter- The thickness of the wire before weaving

8.% Open Area- The ratio of the area of the aperture to the area of the

9.mesh expressed in percentage terms

10.Warp- All wires running lengthwise of the cloth as woven

11.Weft- All wires running across the cloth as woven

About our company

Contact: Zora

Phone: 86-17702223285

E-mail: sales@tjsimpler.com

Whatsapp:86-17702223285

Add: South of Financial Trade Center, No.6975 Asia Road, Tianjin Pilot Free Trade Zone, China

We chat