Material:201 202 302, 304,304L,316,316L stainless steel wire

Wire diameter:0.015-2.03mm

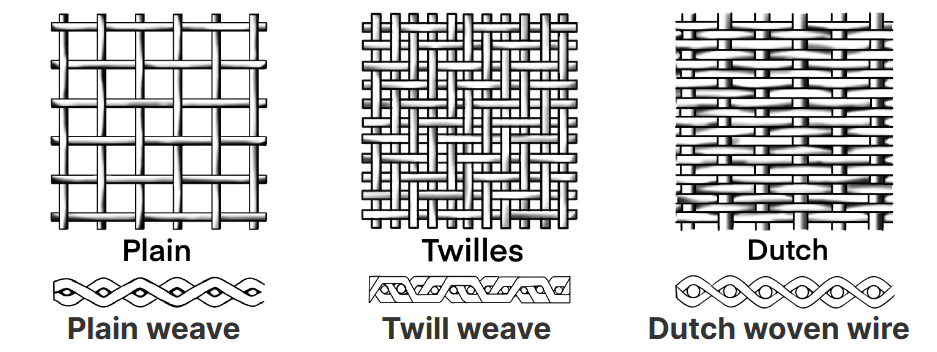

Weave type:Plain/twill/dutch weave

Mesh count:Plain weave can be woven up to 400 mesh.

Twill weave can be woven from 2 to 635mesh.

Dutch weave can be woven up to 500*3500mesh

Reverse dutch weave can be woven up to 350*50 mesh

Product introduction

1.Material:

Common material: SUS201, 304, 304L, 316, 316L, 431, 321 stainless steel wire

Special material: 410/430, 310S, 904L stainless steel wire

2.Wire Diameter: 0.015-2.8mm

3.Mesh counts: Plain/Twill weave: 2-635 mesh Dutch weave:12*64-500*3200 mesh

4. Characteristics:

Strong resistance to impact, anti-theft, bulletproof, anti-mosquitoes, high temperature resistance, flame retardant, high strength, strong toughness;

The surface luster is bright and beautiful, can be better to increase air circulation rate and the light of the sun, with smooth surface, the number of mesh standard, latitude and longitude curve are consistent;

Its remarkable characterstic is as hard as iron hard, anti-theft, bulletproof, home office security first place;

Weaving types and count

1. plain weave, also known as the tabby weave or linen weave, is the most basic and common weaving technique used to create fabric. It is characterized by a simple over-and-under pattern of interlacing warp and weft threads.

2. twill weave is a fundamental weaving technique used to create a specific pattern in fabric. It is characterized by diagonal lines or ribs that are formed by interlacing the warp and weft threads in a particular way.

3. Duch woven wire is a type of woven wire mesh with different diameters and mesh sizes of warp and weft threads. Reasonable combination of wire diameter and mesh size can achieve filtration accuracy that ordinary square mesh screens cannot achieve.

Knowledges of wire mesh

1. Mesh Count = 25.4mm/D+A

2. Aperture= 25.4mm/Mesh count - Diameter

3. % Open Area= A/(A+D)² X 100%

4. Micron= Aperture(mm) X 1000

5.Mesh – The number of openings per lineal inch.

6.Aperture- The distance between two adjacent wires

7.Diameter- The thickness of the wire before weaving

8.% Open Area- The ratio of the area of the aperture to the area of the

9.mesh expressed in percentage terms

10.Warp- All wires running lengthwise of the cloth as woven

11.Weft- All wires running across the cloth as woven

Contact: Zora

Phone: 86-17702223285

E-mail: sales@tjsimpler.com

Whatsapp:86-17702223285

Add: South of Financial Trade Center, No.6975 Asia Road, Tianjin Pilot Free Trade Zone, China

We chat